Challenge/Opportunity

The need to protect products with very smooth surfaces without having to use additional bags as protection;

The chosen solution

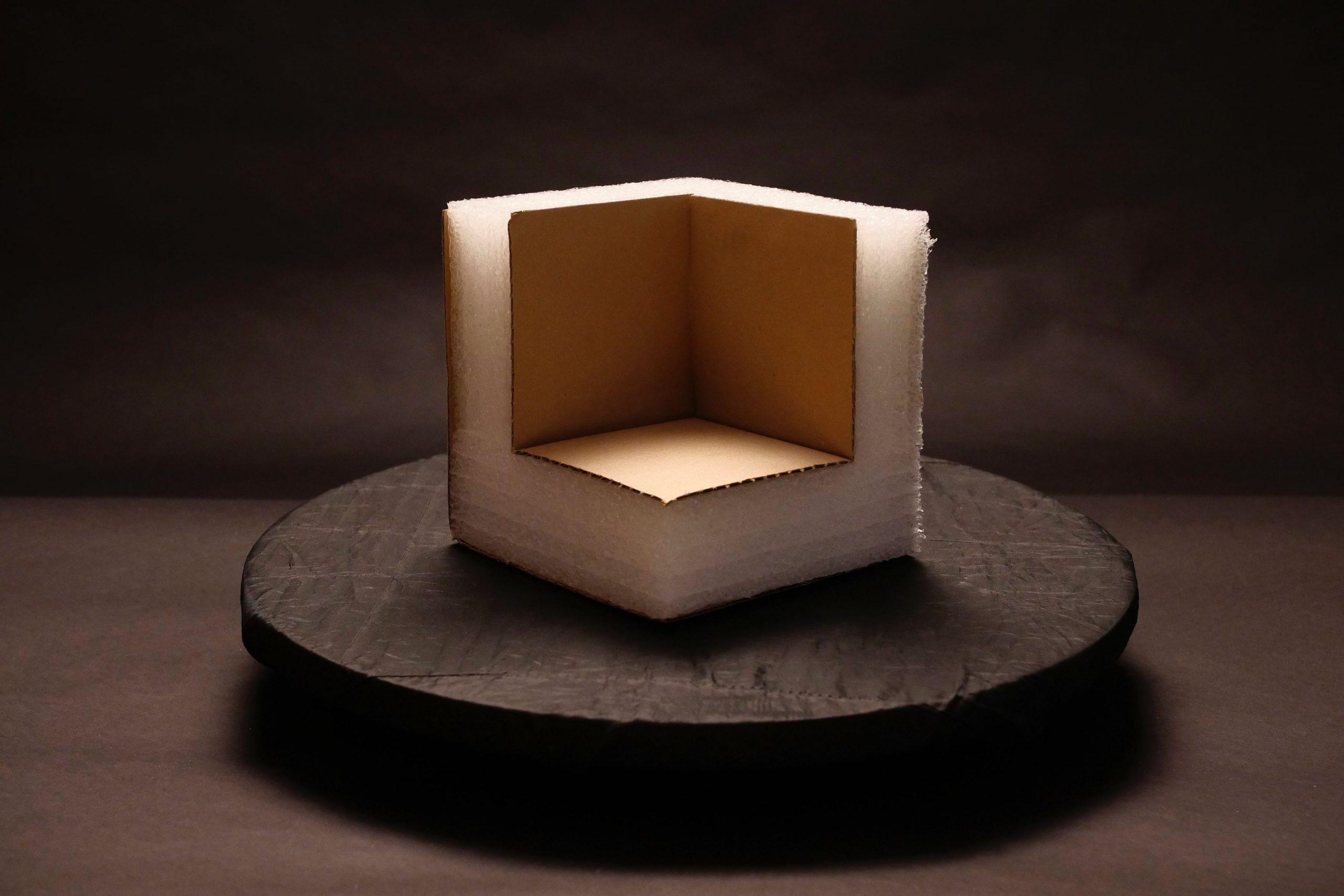

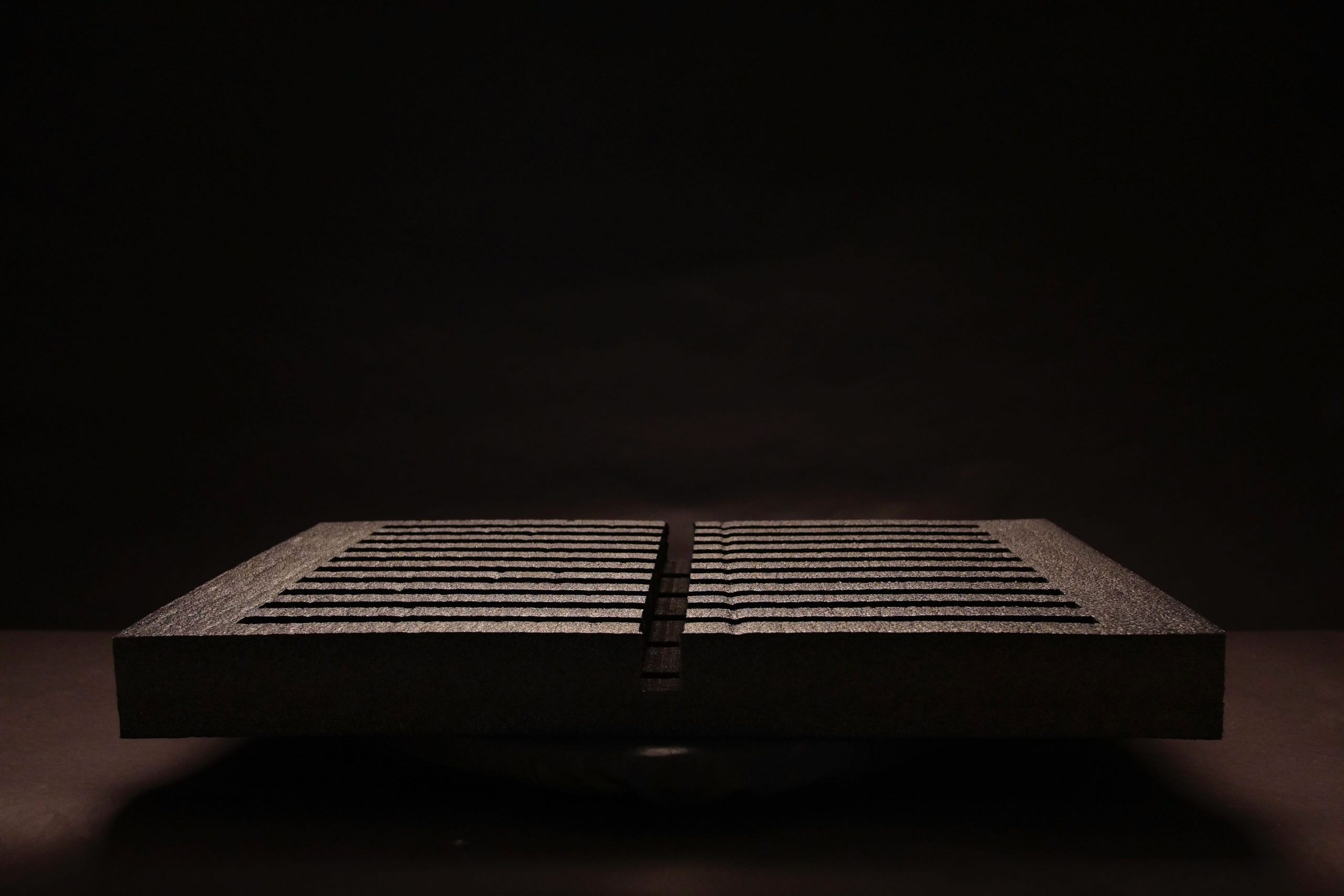

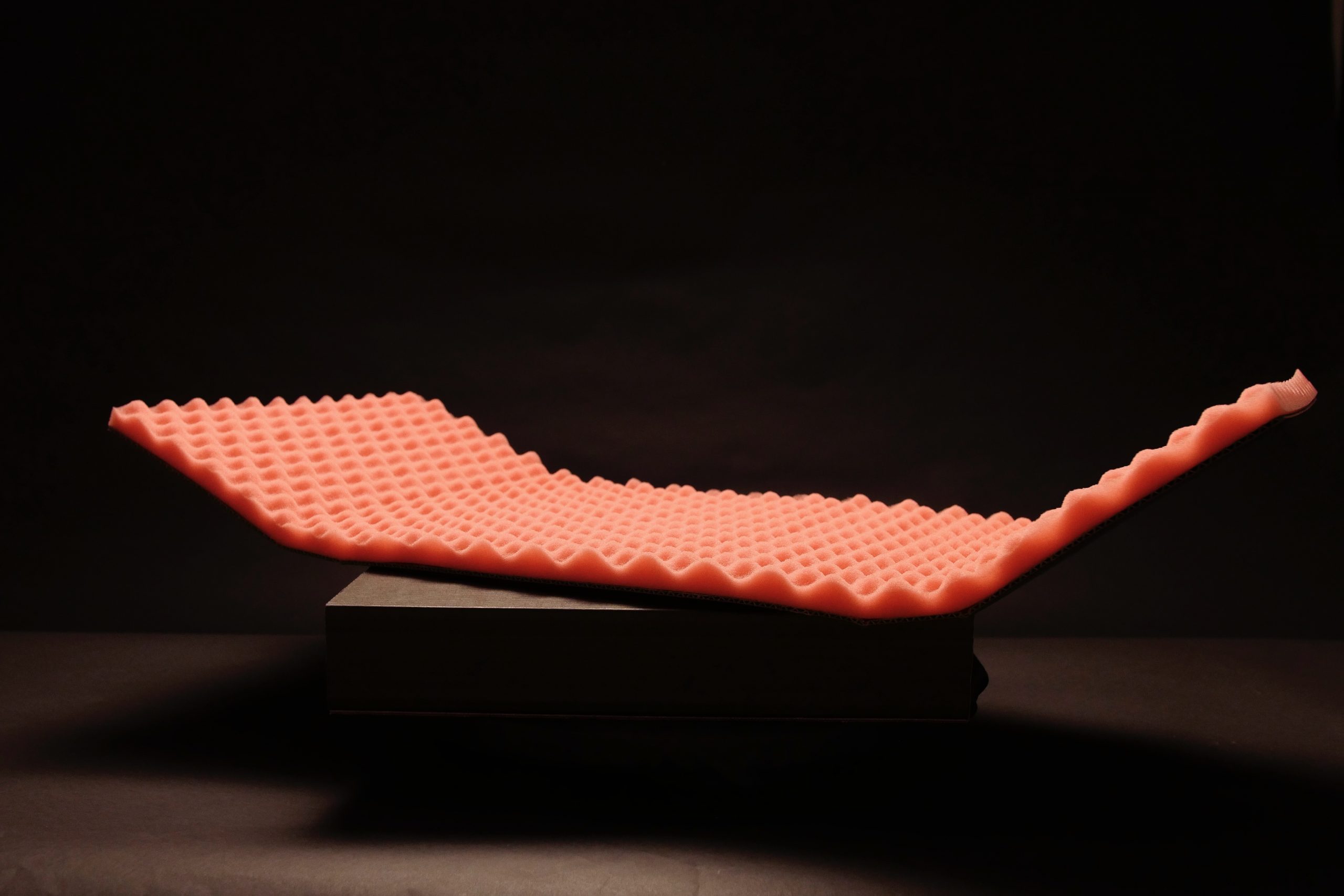

We chose a system composed of B flute corrugated cardboard, with 394 gsm and an ECT of 4.39 kN/m, which we laminated on both sides with an 0.8mm thick EPE film by cold lamination process;

Advantages

- Eliminated the fine scratches on the products and so reducing the scrap rate for the customer;

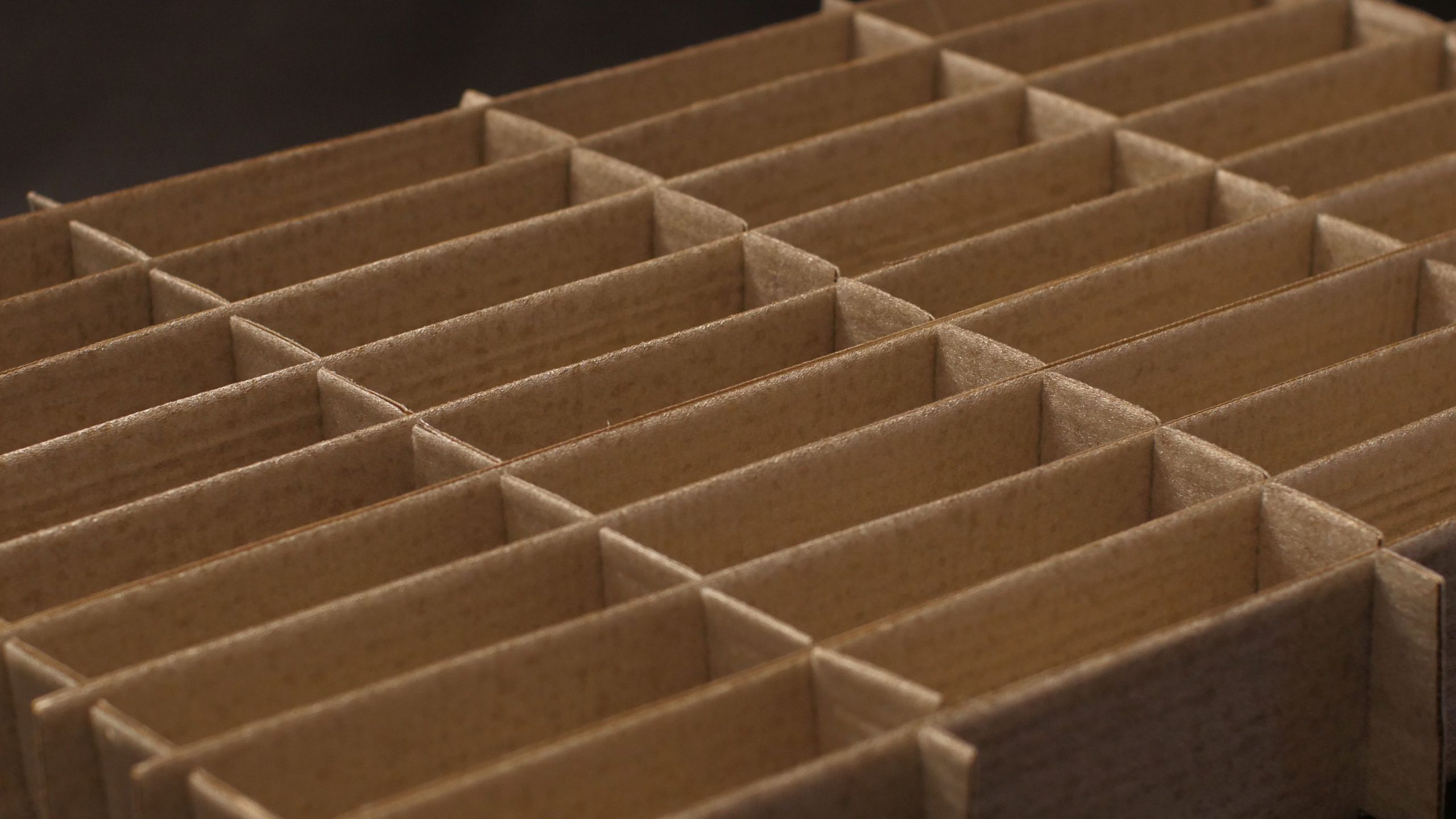

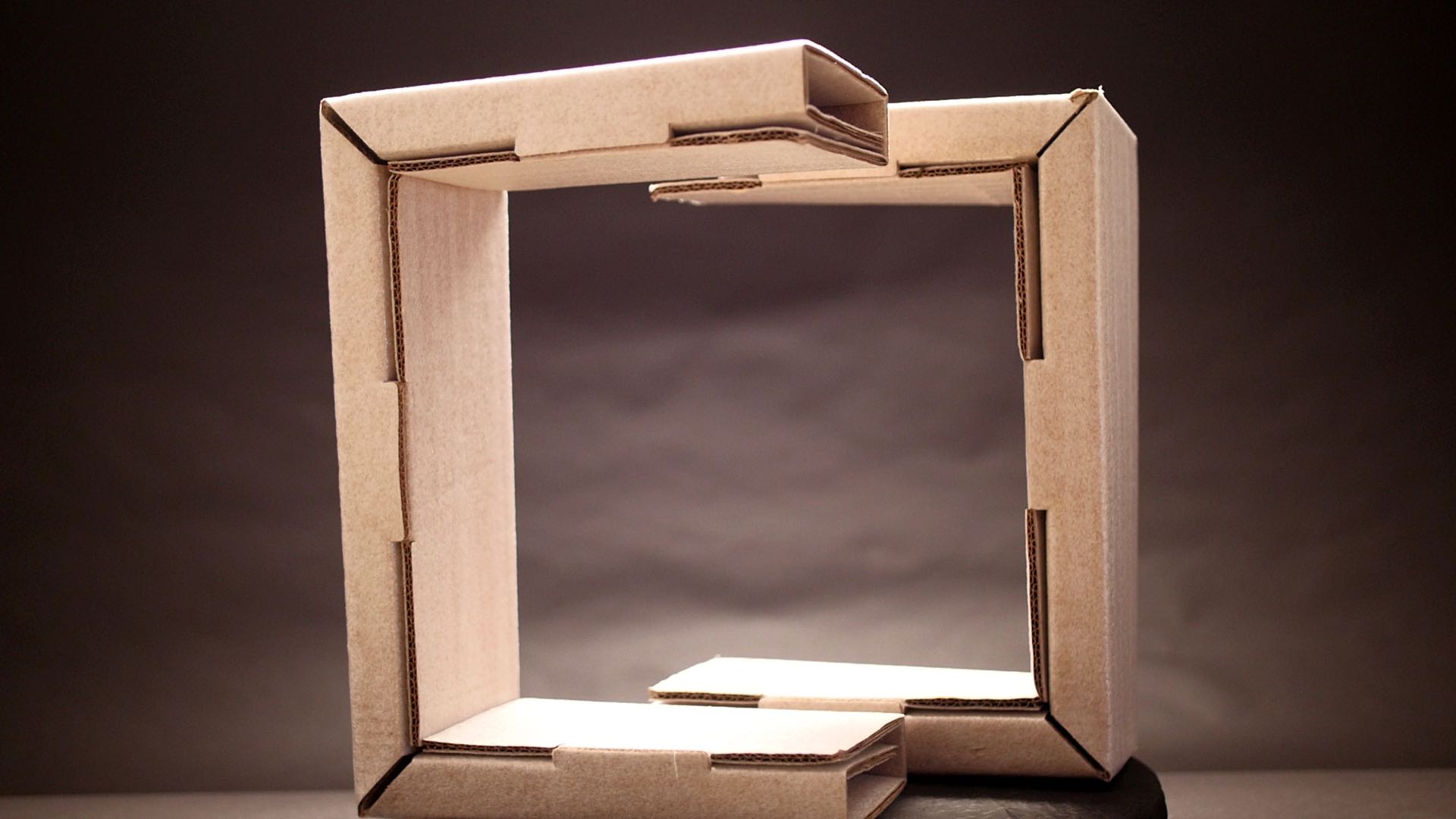

- The parts are now fixed by the separators;

- Each part stays inside its own location in the hive;

- The packing of different products was standardized through new concepts;

- More parts are delivered in the same truck volume;

- Simplified packaging inventory management – from cardboard and foam to a single material;

- Quick packing by having the separators delivered to the client already assembled;

- The separators are delivered folded and by batches corresponding to the layers required for a box;

- The solution is scalable to different product sizes;

- The materials can be ordered with ESD properties – for both cardboard and EPE film;

- The corrugated board can be type B, C, EB and BC flutes;