Challenge/Opportunity

The demand came from the need for a protection system that would withstand heavy loads, and at the same time would ensure the protection of coated materials.

The chosen solution

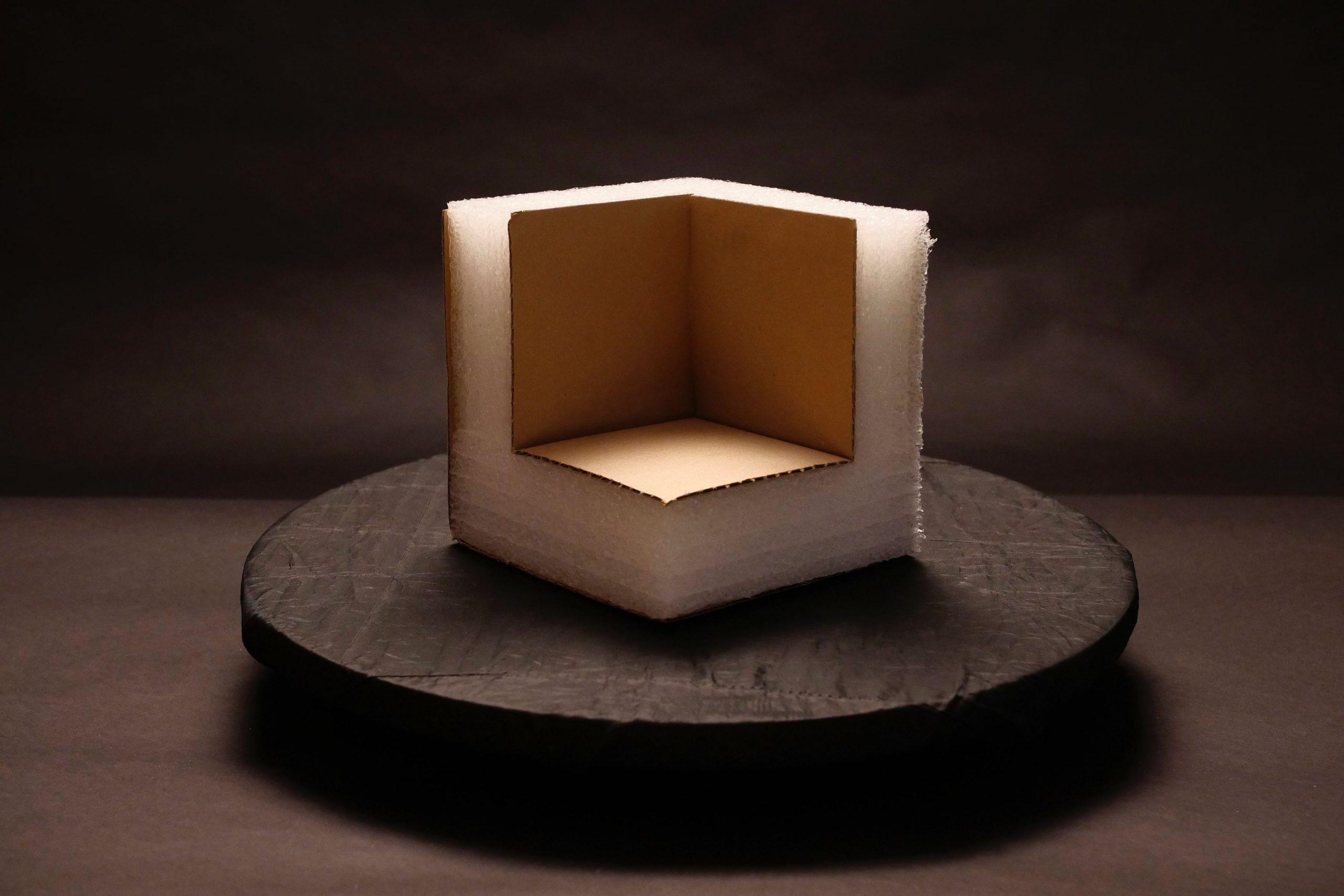

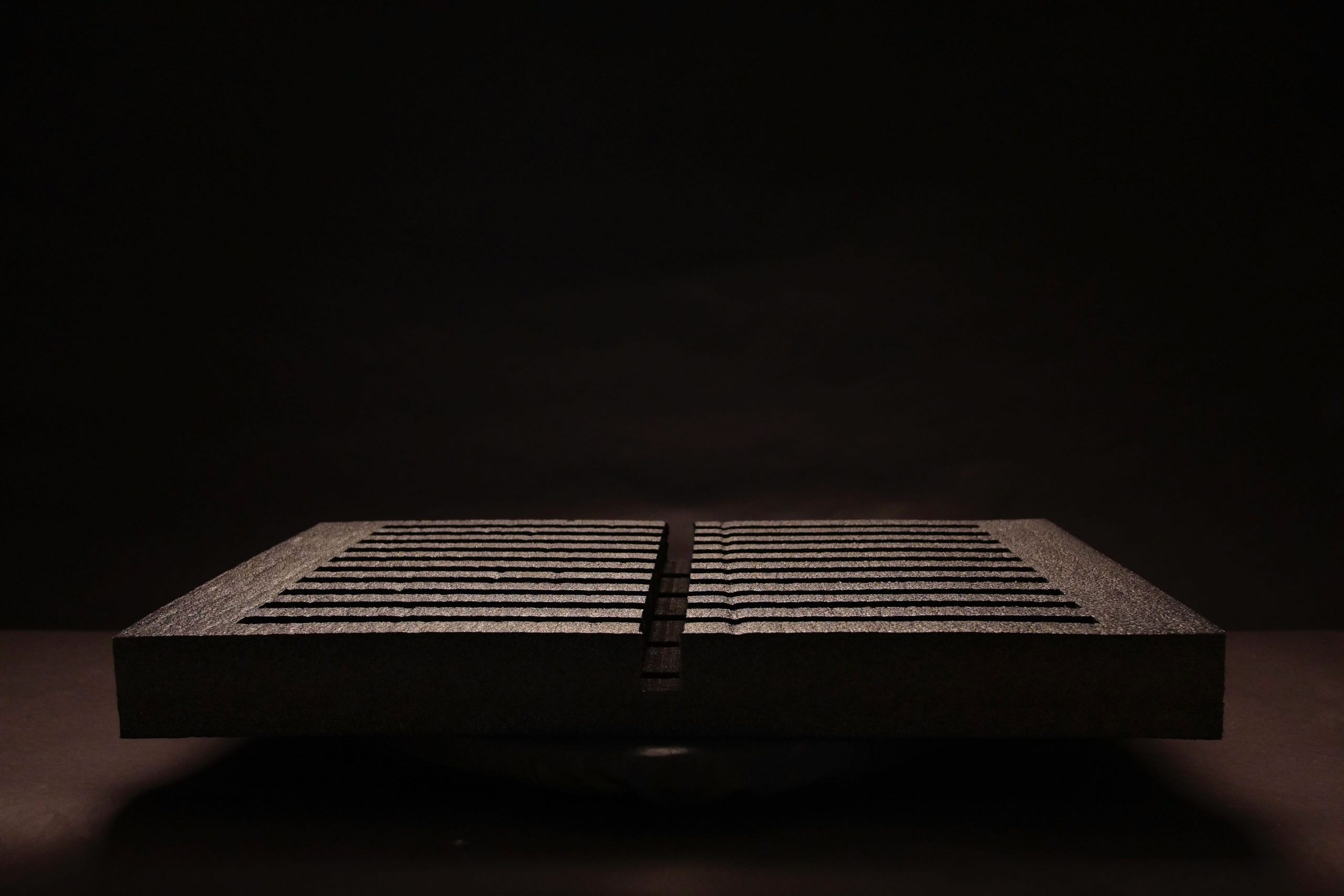

We chose a system that consisted of kraft cardboard with a density of 640 g/m2, ECT of 8.36 kN/m, that was laminated with expanded polyethylene foam. The composite was die-cut to a custom size;

Advantages

- It provides high shock resistance in critical parts, such as the corners of the aluminum housing inside the cardboard box;

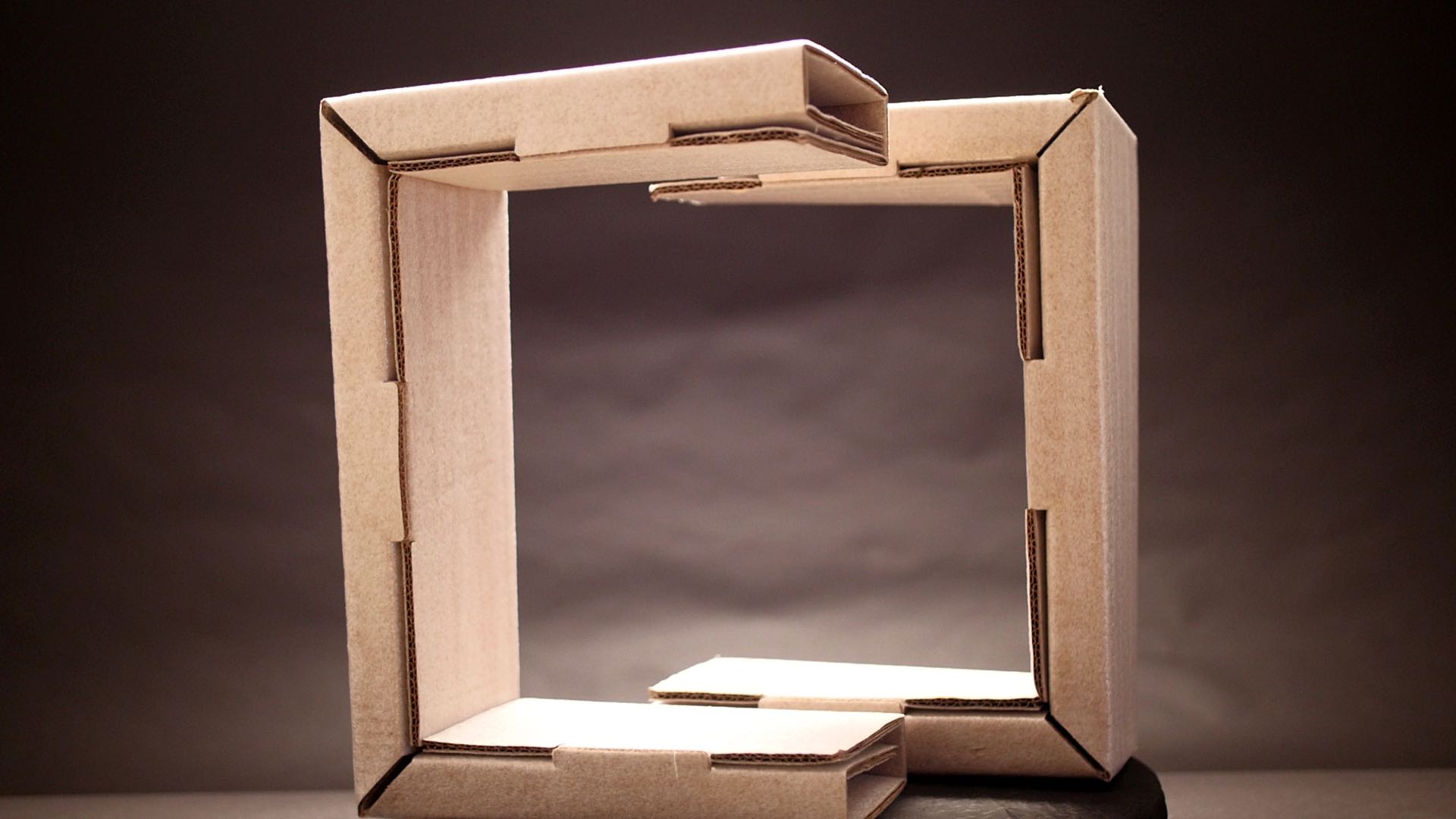

- It can be delivered flat in order to save storing space, but also pre-assembled to save customer`s labour cost;

- Added protection due to better spacing between the housing and the box walls / cardboard layers;

- Effective shock absorbance even after multiple uses across the supply chain;

- Low abrasion for sensitive polished or painted surfaces;

- Enhanced stacking capacity due to the insert’s height alignment with the box;

- The possibility to add new elements or perforations that would allow better securing of irregular-shaped products, or products that contain inserts, handles and other protruding elements;